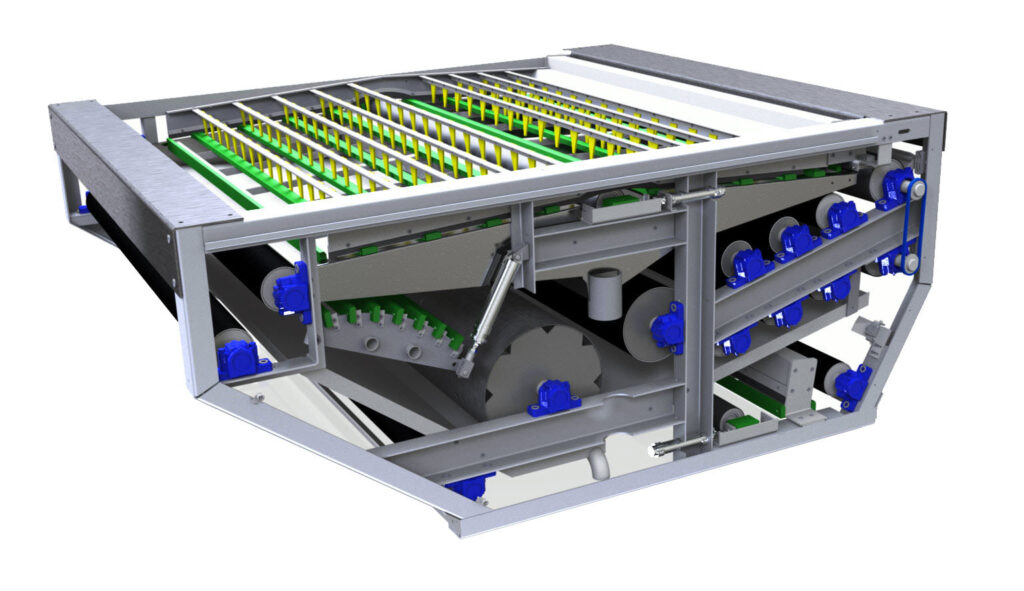

SALTEC Belt Filter Press - CP

Saltec Belt Filter Press is an environmentally acceptable machine with high performance and high reliability.

Information

This is an exceptionally robust machine with an excellent design concept and is suitable for dewatering a wide variety of sludges.

The curvature of the low-pressure zone makes this a very effective machine for its size.

The drainage zone is fitted with self-clearing ploughs which turn the slurry and open new drainage channels.

SALTEC has 3-stage process of dewatering machine:

- Drainage zone: 2.3 meters

- Low pressure zone: 1.7 meters

- High pressure zone: 1.7 meters

Automatic belt tensioning and tracking is operated pneumatically.